F-gases, or fluorinated greenhouse gases, are widely used in refrigeration, air conditioning, and heat pump systems. While they have helped replace ozone-depleting substances, F-gases pose significant risks to our environment and health. This article explores the dangers of F-gases, their impact on climate change, and what you can do to reduce their harm. We’ll also highlight how Logic4training’s expertise and training can help you stay compliant and environmentally responsible.

What Are F-Gases?

F-gases are a group of man-made chemicals that include hydrofluorocarbons (HFCs), perfluorocarbons (PFCs), and sulphur hexafluoride (SF₆). They are used in:

- Refrigeration and air conditioning systems

- Heat pumps

- Fire suppression equipment

- Aerosol propellants

- High-voltage switchgear

F-gases were introduced as alternatives to ozone-depleting substances, but they come with their own set of problems.

Why Are F-Gases Dangerous?

1. Chemical Pollution and PFAS

Some modern F-gases, particularly hydrofluoroolefins (HFOs), break down in the environment to form trifluoroacetic acid (TFA), a type of per- and polyfluoroalkyl substance (PFAS). PFAS are often called “forever chemicals” because they do not degrade naturally and are highly mobile and toxic.

- TFA is now found in rainwater, rivers, groundwater, and even food and beverages.

- Studies have shown that the shift from HFCs to HFOs has led to a significant increase in TFA levels in surface waters, with levels up to 250 times higher in some cases.

- PFAS contamination is persistent, widespread, and difficult to remediate, raising concerns for both environmental and human health.

2. Health Risks

While F-gases themselves are generally not acutely toxic, their breakdown products, especially PFAS like TFA, pose significant health risks:

PFAS exposure has been linked to a range of health issues, including:

- Reproductive and developmental problems

- Endocrine disruption

- Immune system impairment

- Increased risk of certain cancers (e.g., kidney, testicular)

- Thyroid disease and metabolic disorders

TFA and other PFAS have been detected in rainwater, groundwater, and even human blood, raising concerns about chronic, low-level exposure and its long-term effects on public health.

3. Long Atmospheric Lifetimes

A major concern with F-gases is their persistence in the atmosphere. Many F-gases remain in the air for decades, centuries, or even millennia, meaning their warming effects are both long-lasting and cumulative.

- HFCs: Can persist for up to 270 years.

- PFCs: Atmospheric lifetimes range from 2,600 to 50,000 years.

- SF₆: Lifetime exceeds 3,000 years.

Once released, these gases accumulate and continue to trap heat, making even small emissions a long-term problem for the planet.

4. Contribution to Climate Change

F-gases (fluorinated greenhouse gases) are among the most powerful greenhouse gases in existence. Their Global Warming Potential (GWP) measures how much heat a gas traps in the atmosphere compared to carbon dioxide (CO₂), which has a GWP of 1. Many F-gases have GWPs that are thousands, or even tens of thousands, of times higher than CO₂, making them potent contributors to changes in temperature if not handled correctly.

- Sulphur hexafluoride (SF₆): GWP of approximately 24,300 over 100 years, making it the most climate-damaging greenhouse gas in use.

- R-410A (air conditioning): GWP of 2,088.

- R-404A (refrigeration): GWP of 3,922.

Other examples: HFC-134a (GWP 1,430), HFC-125 (GWP 3,500), HFC-23 (GWP 14,800).

Even small leaks of these gases can have a significant impact on the climate. Although F-gases make up only a small fraction of total greenhouse gas emissions (about 2.5% in the EU), their high GWP means their effect on global warming is disproportionately large. The consequences include:

- Rising global temperatures

- More frequent and severe weather events

- Melting ice caps and rising sea levels

- Disruption of ecosystems and biodiversity

Because of their potency, regulations are increasingly focused on phasing down the use of high-GWP F-gases and encouraging the adoption of alternatives with much lower climate impact.

In summary

F-gases are extremely potent greenhouse gases with high GWPs, long atmospheric lifetimes, and the potential to create persistent chemical pollution. Their use and release not only accelerate climate change but also contribute to the growing problem of PFAS contamination, with serious implications for both the environment and human health. Reducing F-gas emissions and transitioning to safer alternatives is essential for a sustainable future.

How Do F-Gases Enter the Environment?

F-gases are released during:

- Installation, servicing, and decommissioning of equipment

- Leaks from poorly maintained systems

- Improper disposal of old appliances

Once released, they are difficult to remove from the atmosphere and can travel long distances, affecting global climate and local environments.

Industry Response

Key UK Regulations

The UK retained the core principles of the EU F-Gas Regulation after Brexit, ensuring continuity in standards and enforcement. The regulation bans the use of F-gases in certain applications, mandates regular leak checks, and requires the recovery and safe disposal of used gases. All technicians handling F-gases must be trained and certified.

Recent and Upcoming Changes (2025 Onwards):

- From 1 January 2025, the sale of new single-split air conditioning systems (with less than 12kW cooling capacity) using refrigerants with a GWP above 750 is banned. This directly affects popular refrigerants like R-410A and R-407C.

- There are ongoing phased reductions in the quotas for placing F-gases on the market, with stricter service bans and phase-downs scheduled throughout the 2020s and 2030s.

- By 2032, only reclaimed or recycled F-gases with a GWP above 750 can be used for servicing and maintenance, eliminating the use of new high-GWP refrigerants.

Compliance Requirements:

- Certification: Engineers and companies must hold valid F-gas certification to work with these substances.

- Leak Checks: Regular leak checks are mandatory for equipment containing F-gases, with frequency depending on the quantity and type of gas.

- Record-Keeping: Detailed records of F-gas use, servicing, and disposal must be maintained.

- Labelling: All equipment containing F-gases must be clearly labelled with the type and quantity of gas.

Enforcement:

Non-compliance can result in civil penalties, fines, and legal action. The Environment Agency and other regulators have the authority to enforce these rules and investigate breaches.

Moving Away from F-Gases

The HVAC-R and refrigeration industries are undergoing a significant transformation in response to the phase-down of high-GWP F-gases. This shift is driven by stringent regulations, environmental targets, and the need for sustainable business practices.

Key industry responses include:

- Adoption of Natural Refrigerants: The sector is increasingly turning to natural refrigerants such as ammonia (NH₃), hydrocarbons (like propane R-290 and isobutane R-600a), and carbon dioxide (CO₂, R-744). These alternatives have negligible or zero global warming potential (GWP) and do not deplete the ozone layer. Ammonia is widely used in industrial refrigeration for its efficiency, while CO₂ is gaining popularity in commercial systems, and hydrocarbons are common in domestic and small commercial applications.

- System Redesign and Innovation: Manufacturers are redesigning equipment to be compatible with low-GWP refrigerants. This includes developing leak-tight systems, improving component durability, and integrating advanced monitoring technologies to detect and prevent leaks. The industry is also investing in research to enhance the safety and efficiency of natural refrigerant systems.

- Enhanced Maintenance and Monitoring: There is a growing emphasis on proactive maintenance and regular leak checks. Improved monitoring practices help identify issues early, reduce emissions, and extend equipment lifespan. Many businesses now offer long-term servicing plans and system audits to ensure ongoing compliance and efficiency.

- Retrofitting and Upgrading Existing Systems: Where possible, older systems are being retrofitted to use lower-GWP refrigerants, helping businesses meet regulatory requirements without the need for complete equipment replacement.

The Role of Training

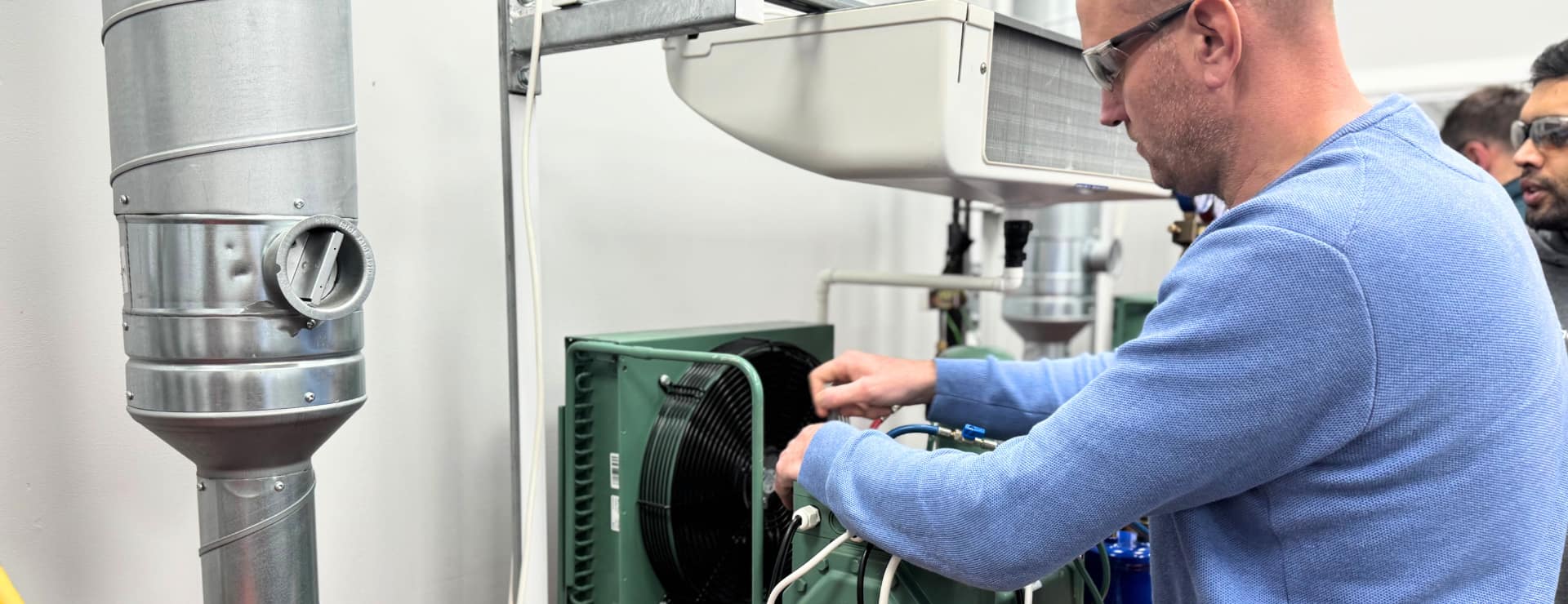

As the industry transitions to new refrigerants and technologies, the need for specialist training has never been greater:

- Identifying and Using Low-GWP Alternatives: Engineers must understand the properties, applications, and safety considerations of natural refrigerants. Each alternative has unique handling requirements and operational characteristics.

- Proper Maintenance and Leak Prevention: Training ensures engineers can maintain systems to the highest standards, minimising leaks and maximising efficiency. This includes best practices for installation, servicing, and end-of-life disposal.

- Regulatory Compliance: With regulations evolving rapidly, ongoing education is essential. Certified engineers are equipped to comply with the latest legal requirements, reducing the risk of fines and ensuring environmental responsibility.

Our refrigeration training courses are designed to address these needs, covering F-gas handling, natural refrigerant alternatives, and environmental best practices. These courses help future-proof engineers’ skills and support the industry’s shift towards sustainability. Our F-Gas courses are developed in partnership with industry experts and meet all legal requirements. We are recognised by DEFRA and offer both practical and theoretical training to ensure you are fully prepared for the industry’s demands.

How You Can Help

Whether you are a business owner, facilities manager, or engineer, you play a vital role in reducing F-gas emissions and supporting the transition to greener alternatives:

- Choose Equipment with Low-GWP Refrigerants: When purchasing new systems, prioritise those using natural or low-GWP refrigerants.

- Ensure Regular Maintenance and Leak Checks: Schedule routine inspections and servicing to detect and repair leaks promptly, improving efficiency and compliance.

- Use Certified Engineers: Always employ engineers with up-to-date F-gas certification for installation, servicing, and decommissioning work.

- Properly Dispose of Old Appliances: Ensure end-of-life equipment is handled by professionals who can safely recover and recycle refrigerants.

- Complete the Necessary Training: If you are already working in the industry or looking to, make sure have completed the correct training and hold the needed qualifications.

- Stay Informed: Keep up to date with the latest regulations, best practices, and technological advances by engaging with reputable training providers and industry resources.

By embracing these changes, the industry is not only meeting regulatory requirements but also contributing to a more sustainable and climate-friendly future.

FAQs

What are F-gases and why are they dangerous?

F-gases are synthetic greenhouse gases used in refrigeration, air conditioning, and heat pumps. They have a very high global warming potential and can persist in the atmosphere for decades or longer, contributing significantly to climate change and chemical pollution.

How do F-gases affect human health?

While F-gases themselves are not usually acutely toxic, their breakdown products, such as TFA, are persistent and can contaminate water, soil, and food, posing potential long-term health risks.

What regulations exist for F-gases in the UK?

The UK follows strict F-Gas Regulations, requiring certification for engineers, regular leak checks, and the use of lower GWP alternatives. Non-compliance can result in fines and legal action.

What are the alternatives to F-gases?

Natural refrigerants like ammonia, hydrocarbons, and carbon dioxide are increasingly used as alternatives. These have much lower GWPs and do not contribute to PFAS pollution.

How can I become qualified to work with F-gases?

You must complete an approved F-Gas training course and obtain certification. Logic4training offers industry-leading F-Gas courses that cover all legal and practical requirements for working with F-gases.