Portable appliance testing (PAT testing) is an often discussed and debated issue in the electrical services industry.

Although the regular testing of electrical equipment was pretty common in government properties, tool hire and other sectors before the introduction of the Electricity At Work Regulations 1989 (EAWR 1989), the legislation was the beginning of a much more widespread application of formal appliance inspection and testing programmes in all workplaces.

The EAWR 1989, which actually came into force on 1st April 1990, set out to raise the standards of electrical safety within industry and commerce. This became the starting point for what is now known as PAT testing.

Despite the uncertainty which initially greeted the introduction of the EAWR 1989, portable appliance testing has now grown into a considerable industry with sophisticated technology making a significant contribution to a safer working environment.

After the introduction of the EAWR 1989, the initial HSE Guidance Note HS (G) 107, published in 1994, was the first comprehensive guide on the in-service periodic inspection and testing of electrical appliances. Based on the advice and experience of experts in various sectors, the initial note attempted, for example, to provide advice on those types of equipment and working environments where a simple visual inspection was enough and those which required combined inspection and testing.

The HSE Guidance Note was then quickly followed by the first edition of the IEE Code of Practice on the in-service testing of electrical equipment. At the time, as the most comprehensive guide published on the subject, this document provided the clearest message yet of the importance of establishing regular electrical safety testing and inspection routines in the interests of workplace safety – and provided more technical information on the tests to be carried out and the suggested inspection and test intervals for different working environments.

Today the custom continues of new HSE Guidance Notes (now called Memorandum of Guidance) being published alongside revised and updated IEE (now IET) Codes of Practice. These are all available to purchase on Logic4trade.

In addition to these documents, in recent years the biggest change to PAT testing has been introduced by the recommendations of the Löfstedt Review in 2012. This review into health and safety requirements sought to bring some clarity to a situation in which it was claimed that the implied legal requirement concerning the maintenance of electrical appliances was being applied ‘too widely and disproportionately’.

In response, the HSE published new guidance on maintaining portable electrical equipment in low risk environments and the IET produced the 4th Edition of its Code of Practice on the in-service inspection and testing of electrical equipment. Both of these guides remain the most up to date formal advice and guidance available to those responsible for maintaining electrical safety in the workplace.

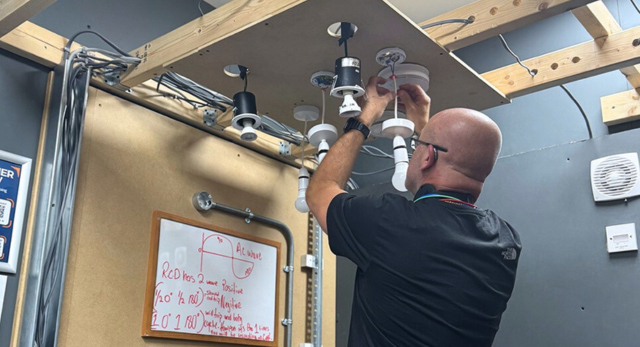

We at Logic4training, have been running a PAT testing course since 2005 and have seen it change over the years.

It is a common mistake for people to think that the qualification is a simple "give-me" type course but even a cursory look through the COP would show you how much is actually involved and that at the heart of this is a requirement for a sound knowledge of electrical testing practices and theory. For this reason our course is now run over 2 days rather than just 1. This allows for more time to understand this comprehensive COP and all that it involves.

It is a common mistake for people to think that the qualification is a simple "give-me" type course but even a cursory look through the COP would show you how much is actually involved and that at the heart of this is a requirement for a sound knowledge of electrical testing practices and theory. For this reason our course is now run over 2 days rather than just 1. This allows for more time to understand this comprehensive COP and all that it involves.

Back to Insights

It is a common mistake for people to think that the qualification is a simple "give-me" type course but even a cursory look through the COP would show you how much is actually involved and that at the heart of this is a requirement for a sound knowledge of electrical testing practices and theory. For this reason our course is now run over 2 days rather than just 1. This allows for more time to understand this comprehensive COP and all that it involves.

It is a common mistake for people to think that the qualification is a simple "give-me" type course but even a cursory look through the COP would show you how much is actually involved and that at the heart of this is a requirement for a sound knowledge of electrical testing practices and theory. For this reason our course is now run over 2 days rather than just 1. This allows for more time to understand this comprehensive COP and all that it involves.