An air source heat pump is an advanced, energy-efficient heating system that extracts heat from the outside air, even in cold conditions, and uses a refrigeration cycle to boost its temperature, providing warm water and heating for your home. Working much like a fridge in reverse, the pump absorbs ambient heat into a refrigerant, compresses it, and transfers the warmth via radiators, underfloor heating, or hot water cylinders, making it a highly effective and low-carbon alternative to traditional boilers for UK homes. This article explains exactly how air source heat pumps work, why they are increasingly popular in the UK, and how Logic4training’s recognised air source heat pump training empowers installers to thrive in the renewables sector.

The Science Behind Air Source Heat Pumps

Step-by-Step Process

- Air Intake: The ASHP draws in outside air, regardless of temperature.

- Heat Absorption: Air passes over a refrigerant-filled coil. Even cold air holds some heat, which is absorbed by the refrigerant, causing it to evaporate and become a gas.

- Compression: This gas flows into a compressor, raising its pressure and increasing its temperature.

- Heat Exchange: The hot gas passes along a second coil inside your home, where it transfers its heat to the heating and hot water system.

- Recirculation: As the gas cools, it turns back into a liquid, and the cycle starts again.

Air source heat pumps operate on a refrigeration cycle that efficiently harvests low-grade heat from the atmosphere and upgrades it for domestic heating, even when outdoor temperatures are below zero. The process begins as a fan draws ambient air over evaporator coils containing a refrigerant with a low boiling point. This refrigerant absorbs even minimal warmth from the air, causing it to evaporate into a gas. The gaseous refrigerant then enters the compressor, where a high level of pressure increases its temperature significantly. This is the heart of the heat pump, and modern scroll compressors allow precise control over heat output and efficiency.

Next, the heated gas travels to the condenser coil inside the property, where it releases its stored thermal energy into water for radiators, underfloor heating, or domestic hot water tanks. Simultaneously, the refrigerant cools and condenses back into a liquid. An expansion valve lowers the pressure of the liquid refrigerant, preparing it to restart the cycle and absorb more heat. This cycling is powered by electricity, not to generate heat directly but to drive the compressor and circulate the refrigerant, resulting in a coefficient of performance (COP) typically between 2.5 and 4.5 in UK conditions.

For every 1 kWh of electricity consumed, a modern ASHP can deliver 2.7-3.5 kWh of usable heat under typical conditions, with the highest efficiencies achieved in mild weather and systems matched to low-flow temperature heating, such as underfloor systems and oversized radiators.

Some air source heat pumps use inverter technology and smart controls to optimise efficiency, defrost external coils as needed, and maintain consistent heating performance throughout the coldest months, overcoming earlier limitations and enabling reliable operation for most UK homes.

Understanding these technical aspects is crucial for installers and homeowners, ensuring the system is properly matched to building size, insulation quality, and heating demands.

Types of Air Source Heat Pumps

Air source heat pumps come in two main varieties:

- Air-to-water

- Air-to-air

Each type is tailored to specific heating needs and property layouts in the UK, with key differences in how they deliver warmth and integrate into your home. By understanding their features, benefits, and limitations, homeowners and installers can make informed decisions about which system offers the best fit for energy efficiency, comfort, and cost-effectiveness.

Air-to-Water Heat Pumps

These systems are the most common choice for homes in the UK. They extract heat from outside air and transfer it into water, which is then circulated through the home by radiators, underfloor heating, or used for domestic hot water. Air-to-water heat pumps require a ‘wet’ central heating system and are eligible for government grants such as the Boiler Upgrade Scheme (BUS), making them an attractive option for homeowners looking to reduce carbon emissions and running costs. Installation is generally more complex, often requiring upgrades to radiators or heating infrastructure to maximise efficiency. These systems work best in well-insulated homes and provide all-year comfort.

Air-to-Air Heat Pumps

These pumps transfer heat from the outside air directly into indoor spaces via a network of fans and ducts, delivering warm air to different rooms. Unlike air-to-water systems, air-to-air heat pumps do not provide hot water, but they can also offer cooling in hotter months, acting as an air conditioning system. The installation is usually simpler and more cost-effective, which makes air-to-air a popular choice for smaller properties, flats, or buildings without wet heating systems. Efficiency can be very high, but grants are not currently available for air-to-air heat pumps in the UK, and the system may require ductwork upgrades for older homes.

Both technologies offer low-carbon, energy-efficient heating, but air-to-water is most suitable for whole-home central heating and hot water, while air-to-air suits zone heating, cooling and properties where water-based heating systems are not present. Understanding these differences helps installers and homeowners pick the right system for their needs.

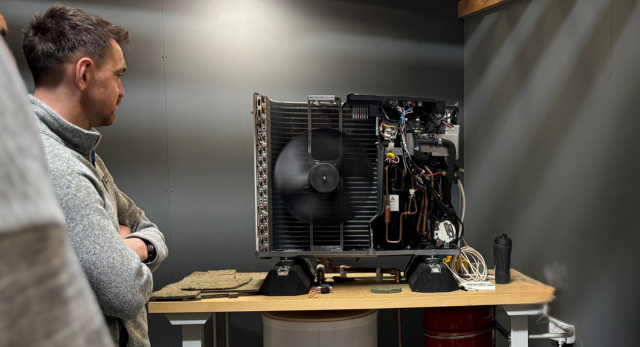

Components of an Air Source Heat Pump

Every air source heat pump is made up of key components that work together to capture, upgrade, and deliver heat efficiently to your home.

The Fans

The outdoor fan draws outside air over the evaporator coil, while air-to-air systems use an indoor fan to circulate heated air within the home, ensuring even and efficient distribution.

Evaporator Coil

Located in the outdoor unit, the evaporator coil is responsible for absorbing heat from the external air, transferring it to the refrigerant and converting it into a gas. It’s this process that allows heat pumps to draw warmth even in cold conditions.

Compressor

The heart of the system, the compressor pressurises the refrigerant gas, raising its temperature and circulating it throughout the heat pump cycle. By boosting both temperature and pressure, the compressor enables heat transfer that is essential for your home’s comfort.

Condenser Coil

After being compressed, the hot refrigerant passes through the condenser coil, usually found indoors, where it releases its heat to the water (for radiators or underfloor heating) or air, before turning back into a liquid.

Expansion Valve

This regulates the flow of refrigerant and crucially lowers its pressure after it releases heat, turning it into a cold liquid ready to absorb warmth from the outside. Without the expansion valve, the system could not repeat its heat absorption cycle.

Reversing Valve (if present)

Essential for systems that offer both heating and cooling, the reversing valve switches the flow of refrigerant, letting a heat pump operate as an air conditioner in summer and a heater in winter.

Refrigerant

Refrigerant is the specialised fluid that circulates continuously through components of an air source heat pump, changing state from liquid to gas and back again as it absorbs and releases heat at each stage of the process. If you intend to work on or handle the refrigeration circuit or the refrigerant itself, you must hold an FGAS qualification. This is a legal requirement under UK regulations to ensure safety, proper handling, and environmental compliance for systems containing fluorinated greenhouse gases.

Control Board and Power Cable

The control board orchestrates every aspect of system operation, managing temperature, flow rates, and safety. The power cable delivers energy to activate the compressor, fans, and electronics.

Understanding the function of each component helps both installers and homeowners appreciate how heat pumps yield consistent, low-carbon heating throughout the year.

Benefits of Air Source Heat Pumps

Air source heat pumps offer a range of compelling benefits that make them an increasingly popular choice for UK homes.

Energy Efficiency

These systems are specifically designed to move heat rather than generate it from scratch, which means they produce significantly more heat output than the electrical energy they consume. With a coefficient of performance (COP) typically between 2.5 and 4.5, a modern ASHP can deliver up to 3.5 units of heat for every 1 unit of electricity used, which results in much lower heating bills compared to traditional boilers, especially as energy prices fluctuate.

Low Carbon

By relying primarily on ambient heat from outdoor air and avoiding combustion of fossil fuels, air source heat pumps greatly reduce carbon emissions associated with home heating. When powered by green electricity, such as from solar panels or renewable tariffs, they can make homes nearly zero-carbon for heating and hot water, contributing to the UK’s net-zero targets and climate goals.

Safe and Reliable

There’s no burning of gas or oil involved in an ASHP system, so homeowners benefit from improved safety with no risk of carbon monoxide leaks or flue emissions. The technology is well proven across Europe and the UK, offering dependable performance and regular, simple maintenance for long-term use.

Eligibility for Grants

The UK government actively encourages the switch to heat pumps through incentives such as the Boiler Upgrade Scheme (BUS). Qualifying households can receive grants towards installation, helping offset upfront costs and making heat pumps a cost-effective investment. These grants support the wider adoption of low-carbon heating technologies as the UK transitions away from fossil fuels.

How Efficient Are Air Source Heat Pumps?

Air source heat pumps maintain efficiency throughout the year, reliably performing even as outdoor temperatures drop to -15°C, which is a key advantage in the UK climate. Their effectiveness is measured by the Coefficient of Performance (COP), which shows the ratio between heat delivered and electricity used. A COP of 3 means the pump produces three units of heat for every unit of electricity consumed. Most modern systems achieve COPs between 2.5 and 4.5, with peak efficiency at milder temperatures and when paired with low-temperature heating, such as underfloor heating or oversized radiators.

Unlike ground source heat pumps, air source models are quicker and simpler to install since they only require an outdoor unit and connection to your home’s existing central heating or ductwork system. This means there is no digging or ground loop installation needed. While system output can decrease as external temperatures drop, advanced inverter-driven heat pumps use smart controls to adapt to changing conditions, ensuring consistent comfort and steady running costs for most UK homes. For best results, correct sizing and good insulation are essential, helping the heat pump deliver warmth efficiently even at the coldest times of year.

Where Are Air Source Heat Pumps Most Suitable?

Air source heat pumps are well-suited to a wide variety of UK property types, delivering the most benefits where certain conditions are met.

For homes without access to mains gas, such as rural or off-grid locations, air source heat pumps provide a reliable, low-carbon alternative to oil or electric heating, lowering running costs and emissions. They are especially appealing to property owners seeking to cut carbon output, meet future energy standards, or take advantage of government incentives like the Boiler Upgrade Scheme.

Buildings with high levels of insulation and existing low-temperature heating systems, including underfloor heating or oversized radiators, are ideal candidates for air source heat pumps. These features enable the heat pump to run efficiently and effectively, ensuring comfortable, consistent warmth all year round.

Air source heat pumps work in both urban and rural settings, thanks to their compact outdoor units, making them practical for homes with limited outside space, extensions, or converted properties.

However, it’s important to note that air source heat pumps are not suitable for every home. Older and poorly insulated buildings may struggle to retain enough warmth from a low-temperature system, leading to reduced efficiency and comfort, unless improved insulation or heating upgrades are made.

Before choosing a heat pump, homeowners should have a professional assessment of their property’s suitability, considering factors such as insulation, current heating layout, and available outdoor space. This ensures the investment delivers the expected efficiency, savings and comfort.

Air Source Heat Pumps and UK Regulations

The most relevant UK regulations governing air source heat pump installations are:

- The Town and Country Planning (General Permitted Development) (England) Order 2015 – Schedule 2, Part 14, Class G: These statutes set out the rules for installing air source heat pumps under permitted development, including the limits on unit numbers, noise levels, locations, and volume. See Regulation G.1 and G.2 for details on allowed numbers per property and compliance requirements.

- MCS Planning Standards – MCS 020 and MCS 020 a): All air source heat pump installations must comply with the Microgeneration Certification Scheme Standard MCS 020 (and MCS 020 a) from May 29, 2025, in England), covering technical, safety, and noise criteria. MCS 020 a) introduces updated sound assessment methodology and lifts the previous restrictions on boundary distances and sizes (up to 1.5m³ for houses, replacing the old 0.6m³ limit).

- Maximum noise level: Under permitted development is 42 decibels at the nearest habitable room window (as dictated by MCS 020 a)).

- Special Cases: Listed buildings and properties in conservation areas may still require planning consent under general planning law.

Before installation, professionals should review current legislation (see Schedule 2, Part 14, Class G of the GPDO and consult the latest version of MCS 020 a) and, where applicable, seek guidance from the local planning authority.

The Installation Process: What to Expect

The installation of an air source heat pump follows a well-defined process, ensuring that your system is safely, efficiently, and correctly integrated with your home’s heating infrastructure. It can be brokendown into the 4 steps below:

- Assessment and Design

- Choosing the System

- Installation

- Commissioning

1. Assessment and Design

The process begins with a detailed heat loss survey and site assessment. This involves evaluating the property’s insulation, existing heating system, window types, room layout, and external space. Installers use this data to calculate the precise heating demand, which directly informs the selection and sizing of the heat pump and related components. Proper assessment is crucial as an undersized or oversized pump can reduce efficiency and impact comfort levels.

2. Choosing the System

For most UK homes, air-to-water heat pumps are recommended, as they integrate seamlessly with central heating systems and provide both space heating and hot water. The decision will also take into account whether radiators or underfloor heating are present and whether upgrades are needed for optimal efficiency. System selection may include choosing inverter-driven models or those with smart controls to further enhance performance and comfort.

3. Installation

Professional, qualified installers will mount the outdoor unit on the ground or an external wall, taking care to position it for maximum airflow and minimal noise disturbance, in line with permitted development standards. The unit connects to the property’s heating distribution system and water cylinder (if present). The installation process involves careful plumbing and electrical work, connection of controls and sensors, and integration with thermostats and home automation if required.

4. Commissioning

Once installed, the system is thoroughly tested, including refrigerant pressure checks, electrical safety, and control functions. Installers optimise the settings for the household’s needs and demonstrate operation and maintenance procedures to the homeowner, ensuring they can safely and efficiently manage the system over time.

Air Source Heat Pump Installer Training

For professionals seeking to upskill in the heat pump sector, at Logic4training, we offer comprehensive, nationally recognised qualifications such as the Level 3 Award in the Installation and Maintenance of Air Source Heat Pumps. The dedicated Air Source Heat Pump Training Course covers practical installation, commissioning, maintenance and regulatory requirements so that engineers gain confidence, competence, become eligible for industry schemes, but most importantly, become qualified to work on air source heat pumps.

Our Air Source Heat Pump Training Course delivers a comprehensive curriculum accredited to the LCL Level 3 Award, covering both theoretical and practical aspects of installation and maintenance for non-refrigerant circuit systems. Candidates will learn to plan, install, commission, and maintain air source heat pumps, as well as diagnose faults and ensure systems meet regulatory standards like MCS. The qualification is designed to prepare engineers for sector demands, offering real-world installation experience and guidance on system design, efficiency optimisation, and compliance.

Entry requirements include recognised plumbing and heating, or Gas Safe qualifications, plus the WRAS Water Regulations. Eligible learners can also access grant funding towards the cost of training, and benefit from Logic4training’s partnership with Alto Energy, streamlining MCS registration and practical support as part of the wider learning journey.

FAQs

Why are air source heat pumps becoming so popular in the UK?

Air source heat pumps are gaining traction because they offer year-round, reliable heating and hot water with much lower carbon emissions and running costs compared to traditional boilers. Supported by government grants, improved building regulations, and ongoing innovations in efficiency and smart controls, they provide a practical route for homeowners to future-proof their heating and play a part in the UK’s push for cleaner, more sustainable energy.

Will an air source heat pump work in my property?

Air source heat pumps are best suited for homes with good insulation, low-temperature heating systems, and available outdoor space; however, older or poorly insulated properties may need upgrades to benefit fully, and a professional assessment is recommended before installation.

How efficient are air source heat pumps compared to traditional boilers?

Modern air source heat pumps typically deliver 2.7 to 3.5 units of heat for every 1 unit of electricity used. This is a much higher efficiency than gas or oil boilers, especially when paired with underfloor heating or large radiators. Performance remains consistent even as temperatures drop to -15°C.

Do I need planning permission to install an air source heat pump?

In England, most domestic air source heat pump installations fall under permitted development regulations, provided they meet specific requirements (such as unit size, location, and noise limits). Listed buildings or homes in conservation areas may need additional planning consent.

What qualifications do I need to install air source heat pumps?

Engineers require industry-recognised plumbing and heating qualifications, such as a level 2 or 3 NVQ or the CCN1 Gas Safe qualifications, alongside the WRAS Water Regulations certificate. Logic4training’s Level 3 Award in the Installation and Maintenance of Air Source Heat Pumps provides the necessary practical and regulatory knowledge to work on air source heat pumps, plus support for MCS registration and sector-specific requirements.