Refrigeration and AC Pipework Oxy-Fuel Brazing Training Course

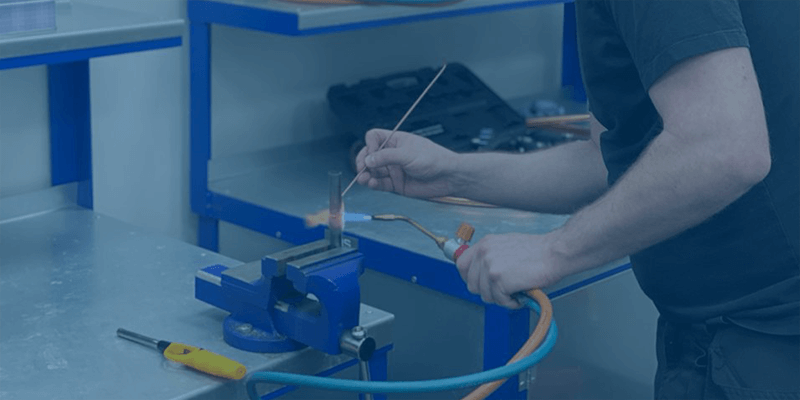

Logic4training's Refrigeration and AC Pipework Oxy-Fuel Brazing Training Course for operatives working within the Refrigeration and HVAC sectors who need to be able to braze to the required standards for either Small Commercial Scheme (1/4” to 7/8”) or Large Commercial Scheme (1 1/8” to 4 1/8”) across a range of pipework materials and brazing alloys using Oxy-fuels.

Refrigeration and AC Pipework Oxy-Fuel Brazing Course Details

This Refrigeration and AC Pipework Oxy-Fuel Brazing Training Course is designed to provide practical, hands-on experience while meeting the safety and competency standards required within the air conditioning and refrigeration industry. Emphasising key brazing techniques for copper-to-copper and copper-to-brass joints, the course prepares participants for the installation and maintenance of HVAC systems in line with current best practice and compliance regulations.

This course is ideally suited for HVAC, refrigeration, and air conditioning engineers who are either new to pipework and brazing or require a refresher in these essential skills. It is also designed for professionals who wish to update or renew their abilities and demonstrate compliance with current industry standards.

This course combines essential theory with comprehensive practical training to ensure you gain the knowledge and hands-on skills required for safe and effective brazing in air conditioning and refrigeration.

Theory

The training begins with a structured theoretical session, providing you with fundamental knowledge of brazing principles and best practices. Trainees receive comprehensive and then complete a short open-book assessment to reinforce learning and confirm understanding.

Practical

The majority of the course is devoted to practical work, focusing on industry-standard techniques for joining copper-to-copper, copper-to-brass, and copper-to-steel pipework. You will gain experience working with a range of pipe sizes:

- Small Commercial Scheme: Pipe sizes from 1/4” up to 7/8”

- Large Commercial Scheme: Pipe sizes from 1 1/8” to 4 1/8”

Practical training includes:

- Pipe preparation and joint construction

- Application of various brazing alloys

- Leak prevention techniques and pressure testing of all joints for quality assurance, followed by destructive testing where required

Throughout the course, you’ll be introduced to:

- Safe working practices for brazing and pipework in air conditioning and refrigeration

- Selection and handling of appropriate materials and consumables

- Equipment set-up and correct use of tools

- Health and safety protocols for hot work environments

The brazing assessment is structured to meet the requirements of EN14276-1:2020 Annex B, which sets out the specification and approval for brazing procedures. This approach provides a recognised method for evaluating and authorising individuals responsible for copper pipework joints under the Sound Engineering Practice (SEP) and Category I of the Pressure Equipment Directive (2014/68/EU) and the corresponding UK Pressure Equipment Regulations 1999 (SI 1999/2001). The assessment ensures compliance with industry safety and quality standards for pressure equipment installation and repair.

Key details:

- LCL Awards Level 3 qualification

- Practical assessment

- In-centre, open-book, online theory test

- Certificate is valid for 5 years

- Price includes for LCL Awards examination and certification fee

Candidates must be working in the Refrigeration and HVAC sectors with some basic understanding of air conditioning or refrigeration.

Personal protective equipment (PPE) will be provided in-centre to be used during the training course.

FAQ's

Oxy-fuel brazing is a process that uses a mixture of oxygen and a fuel gas (such as acetylene, propane, or hydrogen) to produce a high-temperature flame. This flame is applied to the joint area of metal components, heating them enough to melt a filler metal or alloy, which then flows into the joint by capillary action. Importantly, the base metals are not melted, only the filler metal, which allows for the creation of strong, leak-proof joints without altering the properties of the base materials.

The oxy-fuel torch creates a very hot, controllable flame, making it ideal for precise work on copper, brass, and steel pipework, as commonly required in refrigeration and air conditioning installation and maintenance. The method is also referred to as “oxy-acetylene brazing” when using acetylene as the fuel gas, and it is valued for its versatility, portability, and ability to achieve reliable joints in a variety of pipe sizes and materials.

Oxy-fuel brazing is widely used in the HVAC and refrigeration industries to ensure safe, effective, and compliant pipework connections.

Brazing delivers strong, leak-free joints essential for the safety, efficiency, and longevity of HVAC and refrigeration systems. Proper technique reduces refrigerant loss, improves system reliability, and is required for regulatory compliance.

You’ll work on copper-to-copper, copper-to-brass, and copper-to-steel joints, covering both Small Commercial Scheme (1/4” to 7/8”) and Large Commercial Scheme (1 1/8” to 4 1/8”) pipe sizes, using a range of brazing alloys and oxy-fuel equipment.

Successful candidates receive an LCL Awards Level 3 qualification. The certificate is valid for 5 years and serves as proof of compliance with industry standards.

Yes, these are distinct qualifications. While F-Gas certification is needed to legally handle fluorinated gases, this course will focus on brazing skills and can be taken either before or after completing your F-Gas qualification.

This LCL Awards Level 3 qualification provides formal proof of your competence in brazing pipework. It demonstrates that you can produce consistently sound and safe joints that comply with the Pressure Equipment Directive (PED) (EU) 2014/68/EU and the UK Pressure Equipment (Safety) Regulations 2016. This is increasingly important for showing due diligence, meeting site-specific requirements, and proving your skills to employers and clients.

Logic4training will provide all the necessary tools, equipment, and Personal Protective Equipment (PPE), including safety glasses and gloves. We recommend you wear comfortable, non-flammable work clothes and sturdy, enclosed footwear, such as steel-toe-cap boots.

F-gas qualifications for the future of London rail travel