As the UK accelerates towards its net-zero targets, the soaring demand for skilled heat pump installers offers an unmatched opportunity to join one of the UK's most vital and future-focused sectors, supporting communities nationwide in adopting sustainable, energy-efficient heating solutions. This article answers the question of how to become a heat pump installer with the latest training pathways and qualifications, government grants, and expert guidance to help you step confidently into one of the country’s fastest-growing skilled trades.

Training Pathway to Become a Heat Pump Installer

While the pathway is open, not everyone is starting from the same point.

1. Entry requirements for heat pump installer training

Anyone looking to become a heatpump installer must hold one of the following qualifications as well as a valid WRAS Water Regulations qualification:

- A Level 2 or Level 3 NVQ or SVQ in plumbing/heating & ventilation/gas/oil – Installation and Maintenance qualification

- A valid Core Gas Safety (CCN1) certificate with CENWAT – must be involved in the installation of heating systems

- An OFTEC Oil certificate

- A valid HETAS certificate (must be for wet systems)

- CPS registration for plumbing systems

- Two years minimum of verifiable experience on the installation of heating and hot water systems.

For individuals with no experience in the plumbing or gas industry, consider our New Entrant Training Courses to build your plumbing knowledge while preparing for renewables.

2. Air Source Heat Pump Installation & Maintenance (Level 3 RQF) Training

- Covers heat pump technology, system performance, regulations and best-fit application advice

- Includes commissioning, troubleshooting and customer handover (often omitted elsewhere)

- MCS-recognised, so you’re straight onto the eligibility path for grant-funded installs

Completing a Level 3 RQF Air Source Heat Pump Installation & Maintenance training course will allow you to become MCS certified as an air source heat pump installer and work to the MIS 3005-I Standard.

See the Logic4training Air Source Heat Pump Course to begin your training.

3. Low-Temperature Heating & Hot Water in Dwellings Training (Optional – For MCS Design Element)

- Covers detailed room-by-room heat loss assessment, emitter selection for <55°C flow, zoning, and integrating with smart home controls or solar PV.

- Critical for BUS and MCS. This is the overlooked skill, with many failed installs due to poor emitter sizing or lazy “like for like” swaps.

To design heat pump systems that meet the MIS 3000-D standard, you must hold both the Low-Temperature Heating & Hot Water in Dwellings qualification and the Level 3 RQF Air Source Heat Pump Installation & Maintenance qualification.

See Logic4training’s Low Temperature Heating Course.

4. Ground Source Heat Pump Upskill Training (Optional)

- Unlock larger contracts and rural work by upskilling to ground source

- Learn ground loop sizing, borehole design, antifreeze management, and commissioning.

- Flexible add-on after learning ASHP

Lead the market with Ground Source Heat Pump Training.

5. Becoming MCS Certified

Achieving MCS (Microgeneration Certification Scheme) certification is a vital step for anyone serious about delivering heat pump installations that qualify for government grants and win customer trust. Here’s how to make your route as smooth as possible:

- The MCS Standards

Familiarise yourself with the MCS 001 Standard and the specific technical standard for heat pumps. These documents set out the practice, quality, and compliance requirements expected of all certified installers. - Gain the Right Qualifications

You need a recognised Level 3 heat pump qualification, like the LCL Awards Level 3 Award in the Installation and Maintenance of Air Source or Ground Source Heat Pump Systems. These form the technical foundation for your application. - Build a Quality Management System (QMS)

Every applicant must have an effective QMS in place. This doesn’t need to be complex for small businesses. A straightforward set of documents showing how you manage projects, customer care, complaints, and technical quality is enough. Logic4training provides templates and mentoring to help you set this up. - Choose and Apply to a Certification Body

Select a UKAS-accredited MCS Certification Body. Costs typically start from around £700+VAT for the initial application, with annual renewal fees. Your chosen body will audit your paperwork and a real installation to check compliance. - Complete Your First Assessed Installation

Once your paperwork is ready and you’ve completed at least one installation, the Certification Body will assess your project on-site. Passing this audit grants you full MCS installer status, allowing you to self-certify and offer grant-eligible projects to your customers. - Ongoing Compliance

Maintain your QMS and technical standards. MCS certification is renewed yearly with ongoing audits, ensuring quality doesn’t slip and customers remain protected.

You can learn more about how to become MCS certified by reading our article here.

Comparing Ground Source and Air Source Heat Pumps

The key distinction between ground source and air source heat pumps is in the way they collect heat before distributing it through a building.

Air Source Heat Pumps (ASHP)

- How they work: ASHPs absorb heat from the outside air, even in chilly conditions, typically down to around -15°C. This heat is transferred via a refrigerant, which is compressed to increase its temperature before providing heating and hot water.

- Where they’re best suited: Most homes, especially those without large gardens or with limited outside space.

- Installations: Faster and less invasive. Units are usually fitted to external walls or on the ground beside a property.

Pros:

- Lower upfront investment compared to ground source systems.

- Less disruption during installation.

- Typically eligible for government incentives like the Boiler Upgrade Scheme.

Ground Source Heat Pumps (GSHP)

- How they work: GSHPs draw warmth from pipes buried underground, harnessing the earth’s consistent temperature a few metres below the surface. The liquid circulating in the ground loop absorbs this heat, which is then compressed and used to heat buildings.

- Where they’re best suited: Properties with ample outdoor space—especially rural homes or those with large gardens.

- Installation: Involves digging trenches or boreholes—more complex and time-consuming; unsuitable for many urban properties.

Pros:

- Greater efficiency, especially over the long term, as underground temperatures are stable year-round.

- Systems tend to have a longer lifespan since components are less exposed to weather.

Side-by-side Summary

| Feature | Air Source Heat Pump | Ground Source Heat Pump |

|---|---|---|

| Heat source | Ambient outdoor air | Stable underground temperature |

| Typical efficiency* | 270–350% | 320–400% |

| Suitable property type | Most homes | Homes with space for pipes |

| Installation cost (avg.) | Lower (£7,000–£14,000) | Higher (£18,000–£28,000) |

| Installation disruption | Minimal | Major groundwork required |

| Lifespan | 15–20 years | Up to 25 years or more |

| Grant availability | Boiler Upgrade Scheme (BUS) | BUS (usually slightly higher value) |

| Required initial training | Air source heat pump training | Must complete ASHP training first |

*Seasonal Coefficient of Performance (SCOP) varies by manufacturer and installation quality.

Key Takeaways

- Air source systems are more accessible and affordable, making them the most popular choice for British homes.

- Ground source systems, though more efficient and longer lasting, are suited to larger plots and require more investment and groundwork.

- For aspiring installers, qualifying to fit ground source units first requires completion of an air source heat pump course, due to the technical complexity involved.

Heat Pump Installer Earnings Compared to Other Trades

Heat pump engineering has rapidly become one of the most lucrative and future-proof trades in low-carbon heating.

Typical Salary Ranges

| Role | Entry Annual Salary | Experienced Annual Salary |

|---|---|---|

| Heat Pump Engineer | £22,000 | £45,000 |

| Gas Engineer | £18,000 | £38,000 |

| HVAC Engineer | £20,000 | £35,000 |

- Heat pump installers can earn up to £10,000 more than peers in other heating and ventilation roles, largely due to the specialist skills required and high demand for renewables expertise.

- Income potential rises further for those running their own business, delivering consultancy, or branching into commercial or large-scale domestic installations.

- The market rewards upskilling: The more qualifications and practical experience you gain, such as advanced system design or MCS certification, the higher your earning potential and the more competitive your service offering.

The UK Government’s Heat Pump Ambition & Why It Matters for Your Career

Demand for energy-efficient heating is surging. With gas boilers facing phase-out for new homes by 2025 and ambitious government targets like 600,000 heat pump installations per year by 2028, the sector needs skilled, adaptable engineers more than ever. Homeowners, landlords and businesses are under pressure to decarbonise and need trusted, well-trained professionals to guide them.

Progress in Installations

- Annual installations: In 2024, the UK recorded its highest ever number of certified heat pump installations with almost 60,000 units, marking a 43% increase over 2023. This growth was further topped by a record-breaking start to 2025, with over 15,700 certified installations in the first quarter alone. March 2025 alone saw 5,600+ installations, a 22% rise compared to March 2024.

- Cumulative installs: By mid-2025, the UK surpassed 250,000 certified heat pump installations, reflecting sustained acceleration in adoption.

- Growth context: For further perspective, 2024 sales saw a 63% overall surge in hydronic heat pump sales and a 15% increase in individuals completing recognised heat pump training qualifications.

- 2028 target: Despite these gains, the UK is still scaling up towards the government’s ambitious target of 600,000 heat pumps installed annually by 2028. This goal was reaffirmed in 2025 and is intrinsically linked to net zero by 2050.

Workforce Growth & Installer Numbers

- Installer growth: The number of qualified heat pump installers in the UK has risen dramatically. From just under 3,000 in 2022, the sector surged to roughly 8,000 by 2023 and is now estimated at over 11,000 trained individuals. However, projections indicate the UK needs around 33,700 full-time installers to meet its 2028 targets, highlighting a significant gap but strong ongoing progress.

- Training increase: In 2024 alone, 9,062 individuals completed a recognised heat pump qualification, a sign of the sector’s investment in upskilling.

Financial Incentives and Impact

- Boiler Upgrade Scheme (BUS): Demand has surged with the BUS grant increased to £7,500, making it one of Europe’s most generous schemes. The Boiler Upgrade Scheme (BUS) has ramped up investment year-on-year, with £50,029,000 spent in 2022-2023, £88,430,500 in 2023-2024, and a substantial £189,287,500 in 2024-2025, leaving nearly £190 million available for installations in 2025-2026. This rising budget reflects strong demand for heat pump installations and ensures continued support and opportunity for both consumers and installers.

- Market impact: This direct consumer grant continues to underpin both demand among homeowners and job growth for installers.

How the Statistics Inform Your Career Prospects

- Sector momentum: Nine of the UK’s ten busiest ever months for heat pump installations occurred between May 2024 and March 2025. 2024 was also the only large European market to see growth, as much of the continent slowed down.

- Workforce transition: With government and industry support, the number of trained and qualified installers is rising quickly, but demand still far outpaces supply. There is a substantial opportunity for gas engineers, plumbers, and heating professionals willing to upskill.

Summary Table: Latest UK Heat Pump Stats (2024–2025)

| Metric | Latest Data/Period |

|---|---|

| Certified UK heat pump installations | ~60,000 in 2024 |

| Q1 2025 certified installations | 15,758 |

| Cumulative certified installations | Over 250,000 (May 2025) |

| Year-on-year growth (2023–2024) | +43% |

| Installers trained (2024) | 9,062 |

| Current trained installers (2023–2024) | >11,000 |

| Target for annual installs by 2028 | 600,000 |

| Estimated installer target for 2028 | 33,700 |

| BUS grant (as of 2025) | £7,500 |

Key Takeaways

- Heat pump adoption in the UK is at a record high, with installations up sharply in 2024 and early 2025.

- The field is fast-growing but still far short of government targets, creating unmatched demand for qualified installers.

- Industry-backed schemes, generous grants, and increased training opportunities underscore that now is an ideal time for skilled tradespeople to transition to heat pumps.

Staying up to date with the numbers not only highlights the scale of opportunity but also the urgency in training and certification for those wanting to shape the future of domestic and commercial heating in the UK.

Career Potential & Next Steps

Whether employed or self-employed, investing in ongoing training and staying up to date with new technology not only raises your salary prospects but also positions you as a leader in a sector set to expand rapidly in the coming years. Leveraging modern job management software can support growth for independent businesses, helping you streamline operations and maximise your opportunities in this fast-moving field.

Why Train With Logic4training?

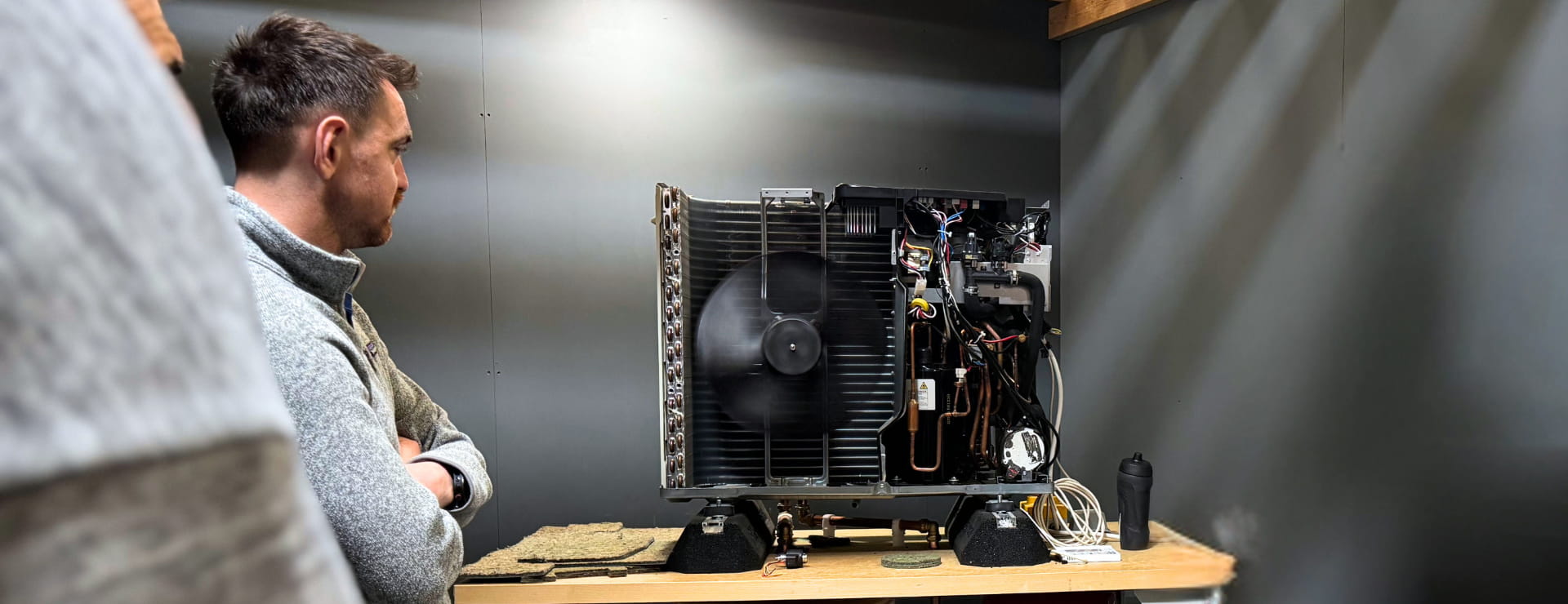

- Three dedicated Green Energy Centres (Northolt, Sittingbourne, Basildon) with live ASHP rigs and training simulations.

- Industry leadership: our director sits on the HPA and LCL Awards committees, shaping course standards.

- State-of-the-art facilities: we set the industry standards with modern, up-to-date facilities with small class sizes.

- End-to-end pathway: from new entrant training in plumbing and gas training to specialist heat pump training and guidance on how to become MCS certified.

Here what our heat pump candidates had to say about our training:

FAQs

How long does the whole process take from first training to MCS registration?

With prior plumbing and heating experience, you can become fully qualified and MCS-ready within 4-6 weeks if you train full-time, including portfolio gathering. Those new to the trade might take 6- 12 months depending on foundational course choice.

What’s the average income for an MCS-registered heat pump installer?

Most earn £45,000–£60,000 per year (self-employed), with experienced installers or business owners often exceeding £65,000. Maintenance contracts and design consultancy offer additional revenue streams.

Do I need F-Gas?

Only for split-system installations. 70% of UK installs use monobloc units, but F-Gas is valuable for future-proofing your offering as hybrid systems become more popular.

What technical documentation is needed for each job?

You should leave: commissioning sheet, design calculations, handover pack (including user guide), and a CB check (if necessary)—all are available as Logic4training templates.

What CPD options are available after initial certification?

Annual update courses on regulation changes, new control systems workshops, troubleshooting clinics, and peer-to-peer roundtables are hosted at Logic4training centres.

Ready to fast-track your career?

Contact our expert team on 020 8845 7222, explore upcoming course dates, or join our next open evening for a hands-on demo and one-to-one career advice.